Our tools can be used for all bolting tasks in production, assembly, repowering and service: onshore and offshore according to manufacturer specifications. We assemble specific tool sets for your various bolting tasks for all types of wind turbines and develop task-specific assembly aids.

Your advantages at a glance:

- Tower, hub, nacelle and rotor blade bolting systems

- Easy and fast work even in hard-to-reach places

- Automatic quality documentation

- High work safety due to special solutions

- Manufacturer-specific assembly aids

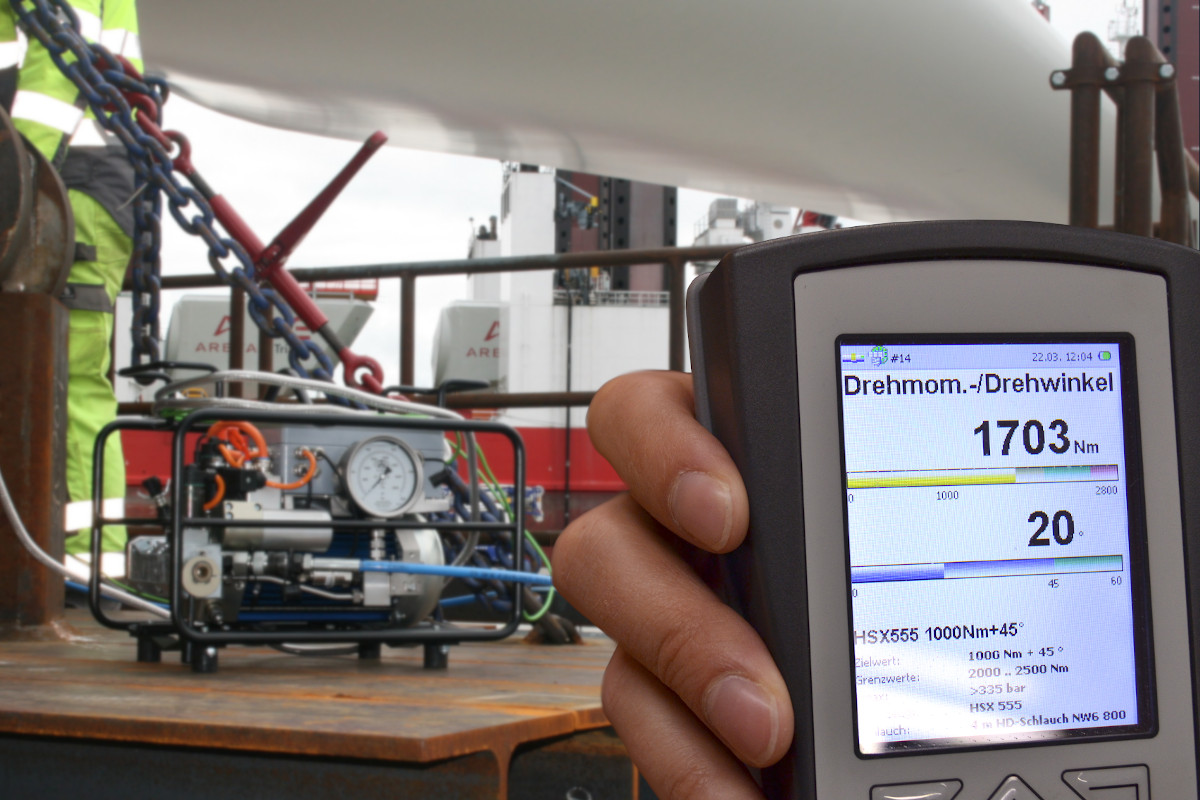

- Can be combined with external measuring devices

- Devices for the torque-angle method

Our solutions for the wind energy

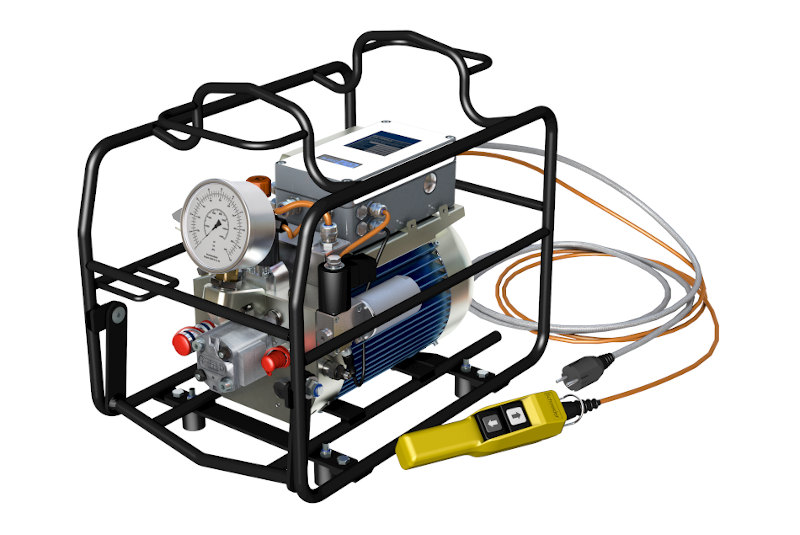

Manufacturers and service companies of wind turbines worldwide rely on PLARAD’s comprehensive system solutions. Whether production, assembly or maintenance – our bolting tools are reliable, easy to use and guarantee the safety of your employees. From the rotor blades, to the hub, to the foundation – our hydraulic and electric tensioning and bolting tools are versatile. Thanks to our smart hydraulic units, you gain additional added value – you can seamlessly record your bolting data and thus make your processes even more efficient.

Your advantages

- Two-hand operation prevents intrusion into the hazardous area

- Safety Start Trigger (SST): unit stops automatically when one of the two triggers is deactivated

- 360° rotatable joint for recoilless operation and flexible positioning on the screwdriving case

- Torque range up to 8,000Nm

Your advantages

- Storage of 10,000 bolting cases

- Wireless transmission via WLAN module

- Torque/angle mode

- Torque test mode

- The light weight and the well-engineered ergonomic

profile enable good handling

Your advantages

- The automatic pump controls and terminates the tightening process fully automatically, even in the case of multiple tightening operations, and displays this on the remote control unit

- With the Plarad units, all tightening torques and further tightening angles performed are stored in the operating unit